Services

Here is a collection of our services

Own project scenario

GEG actively identifies, builds and invests in new development opportunities. The initial stage of a project is feasibility assessment. Profitability, contractual terms, project country situation and logistics are some of the factors which decide if a development goes ahead.

Projects which progress beyond the early elimination stage are subjected to more specific internal financial modelling, design and production which culminate with a draft business plan / project overview document.

Tendering scenario

Another key target area for GEG is large international tenders for IPP and EPC developments. The attractiveness of the projects varies greatly according to the tender offer, works requested and country risk.

If taken on board, a tender bid (or request for qualification) is prepared and submitted to the relevant authority. GEG maintains good communication with the tendering organisation, providing any clarifications requested and follows up on the bid up until the decision date and award of contract.

Financing

Track record

GEG is well connected in the industry and has a history of cooperation with some of the largest global financing institutions. Most recently, we secured World Bank backing for the ongoing Maldives project.

Through work on tenders and in different countries, we accumulated significant experience in structuring projects and optimising equity/debt ratios, debt service coverage, repayment methods and alike.

GEG has the reputation and ability to negotiate favourable financing terms with the biggest of lenders. High debt funding percentage, long repayment or grace periods are some of the items we were able to obtain for our projects.

Additional services

In case of Independent Power Producer (IPP) projects, we are also able to advise on PPA terms, insurance and optimal structuring of the project company in different countries with regards to administrative and tax matters.

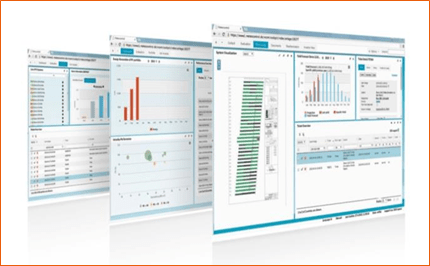

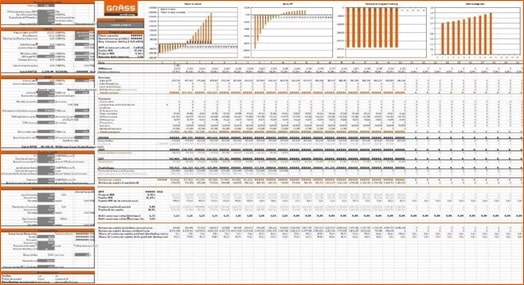

Whether supporting the client in financing a project or obtaining funding for own developments, GEG utilises a sophisticated financial model which has the flexibility to accommodate for country-specific risk, costs, tariffs, irradiation among others. Undertaking evaluation of economic efficiency of a project and creation of business plans are part of our regular scope of work hence we can also offer expertise in this area.

Project Development

Site selection

A photovoltaic power plant is an investment promising sustainable long-term profit. One of the key methods of achieving success is choosing the ideal project site.

In case a client has not yet chosen and secured their project site, we can suggest them a suitable location. With our wide-spread network of subsidiaries and partners, we are able to offer project site services throughout Europe as well as worldwide, taking into account the geographical and economical options as well as the political and legal background.

Design and permits

GEG can implement a complete project development service from acquiring the site to full turn-key construction, or only to a ready-to-built status.

Our services include economic models and the creation of a business plan as well as the administrative process to obtain all permits necessary for construction.

In close cooperation with the utility we plan the layout of the cable lines and the grid connection point and obtain the feed-in tariff contract, if applicable.

Ground-Mounting Solutions

GEG designs and offers mounting structures which are developed in-house and constantly improved based on experience in previous projects. These include sophisticated fixed mounting structures, as well as tracking solutions which dynamically adjust the angle of the panels and can make solar PV profitable even in regions without optimum irradiation.

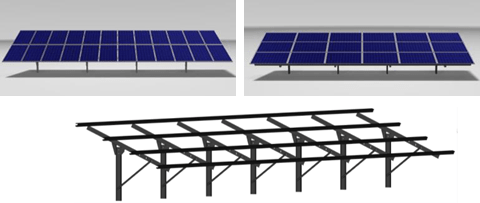

Fixed frame

The traditional GEG steel frame mounting solution which has been used on hundreds of MWs. In terms of panel configuration we focus on a two portrait solution for conventional solar PV modules and on a three landscape solution for double-sided solar PV modules.

The structure accommodates for tilt angles of up to 35° towards south (for PV modules) and lateral inclination of up to 30° towards east or west (for the whole structure) while mounting posts remain in vertical position.

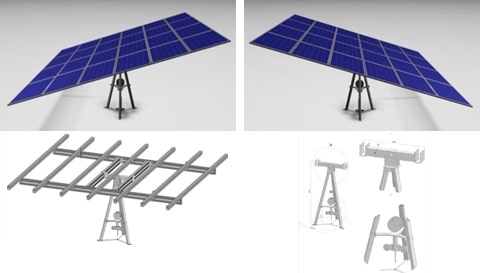

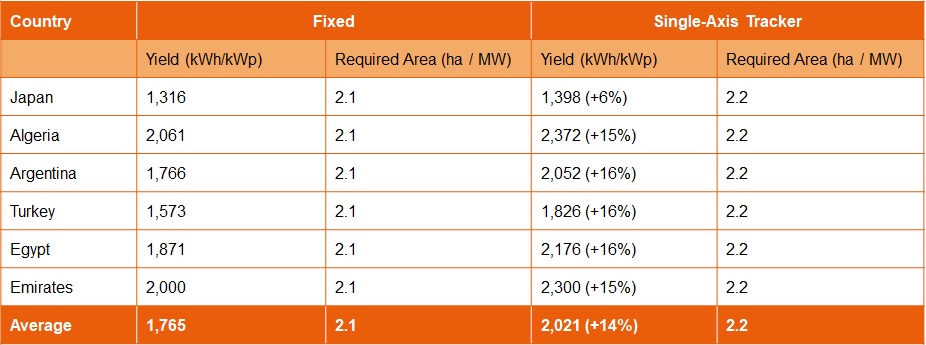

Single-axis tracker

The single-axis tracker’s module table is tilted by a single motor along the east-west axis and it replaces the old version based on the 2 portrait fixed frame. The angle changes automatically during the day but can also be modified for storm situations (0° tilt) or maintenance (up to 40° tilt).

The standard configuration for this tracker is four rows with six modules in portrait orientation (24 modules per tracker) using 60-cell modules. Smaller tracker configurations which are also suitable for rooftop installation are available on request.

Engineering

PV power plant planning and layout

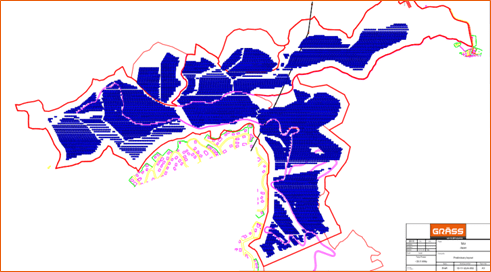

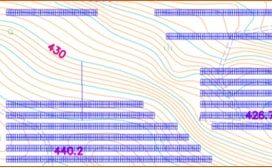

GEG offers a broad range of services for all planning phases in order to deliver the optimum PV power plant layout. Planning work for a PV power plant is usually split up in different phases: preliminary layout, modification of layout, detailed

layout and adaption during construction.

To achieve this goal, our experienced team of project engineers and draughtsmen utilises latest software such as AutoCAD Civil 3D, Helios and PVSyst.

Mounting and cabling optimisation

Since GEG offers different mounting solutions a part of the technical design is the selection of the optimal framework with regards to electricity generation and land utilisation.

Subject to circumstances, cabling can represent a significant portion of the project cost and we are able to minimise this with appropriate design and positioning of the panel frames, inverters, switchgear in relation to each other and the grid connection point.

Component selection and string layout

The string layout for the PV power plant is defined according to geographical situation and local conditions such as solar irradiation and temperature profile. Furthermore PV modules and inverters are selected so their characteristics maximise performance with the given string layout.

In addition, local conditions are considered when selecting a mounting structure as reinforced structures or deeper foundation may be required due to snow and wind loads.

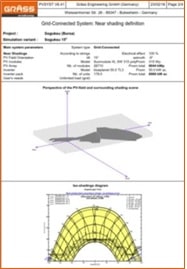

Shading-optimised plant layout

Shading of PV modules and strings decreases overall yield and revenue of ground-mounted as well as roof-mounted PV systems. Therefore, shading-optimised layout is key to economic success of every project.

GEG engineers every project using sophisticated analytical methods to ensure shading-optimised layout even on hilly ground. This is done by appropriately partitioning the power plant area and adjusting the distance between each row and area individually while taking shading into account.

Following this approach installed power is optimally adapted to fit available PV power plant area while shading-related yield losses are reduced.

On-site tests

The results of the planning phase are checked on-site. After performing a GPS based survey of the area (see middle image) to mark piling post positions, structural evaluation of the components is carried out, taking into account local terrain as well as weather and climate conditions.

Test ramming analysis ensure the solidity of the ground. Load tests simulate the influence of wind, snow, and other static loads (see image to the left). If necessary, our team would remove bushes and trees and level the site.

Other services

We also provide coordination of geological, ecological, environmental or other surveys as well as integration of outside companies and specialists for services such as structural analysis or extensive civil works.

If waste or historical fragments are found, GEG coordinates the appropriate clean-up of the site in cooperation with responsible authorities, if applicable.

Construction

Standard GEG construction works:

Soil test, test ramming, and load tests; GPS-aided measuring; Lumbering; Fencing and security; Construction site set up; Civil works and preparation of foundations; Piling of piling posts and installation of module structure; Module installation; Inverter and switchgear installation; Electrical installation DC and AC; Documentation and commissioning

Project management

GEG offers overall project management as well as services such as time planning and implementation schedules. We strive to do projects to a turn-key standard independently but we can provide subcontractor management if applicable – for instance, when there are local content requirements in tenders.

Reputation

For years the foundation of GEG has been turnkey EPC works on solar PV plants hence in terms of experience and installed capacity we are able to match any competitor on the market. With our specialised team and company-owned machinery, we have completed even highly complex projects within the shortest possible time. We handle the intricate logistic tasks required to finish any size PV projects entirely on our own or in cooperation with subcontractors.

Operation & Maintenance

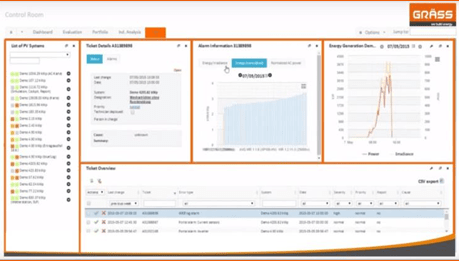

Latest monitoring technology

After completing a power plant, we offer our clients to operate, maintain, clean, and monitor the PV power plant in order to guarantee a sustainable performance ratio.

Using cutting-edge monitoring software, we are able to provide real time remote control of the PV system. For instance, the program is capable of pin-pointing the exact defect / underperforming string and providing data which may enable us to resolve the issue without visiting the site.

On-site support

In case of failure which cannot be fixed remotely, we have local teams of engineers available to react immediately (see global locations page) and correct any relevant problem on site.

Through the combination of sophisticated technology, international presence and experience with operation of past projects, GEG provides a high level of support and an operation & maintenance contract with us brings any plant downtime to a minimum.